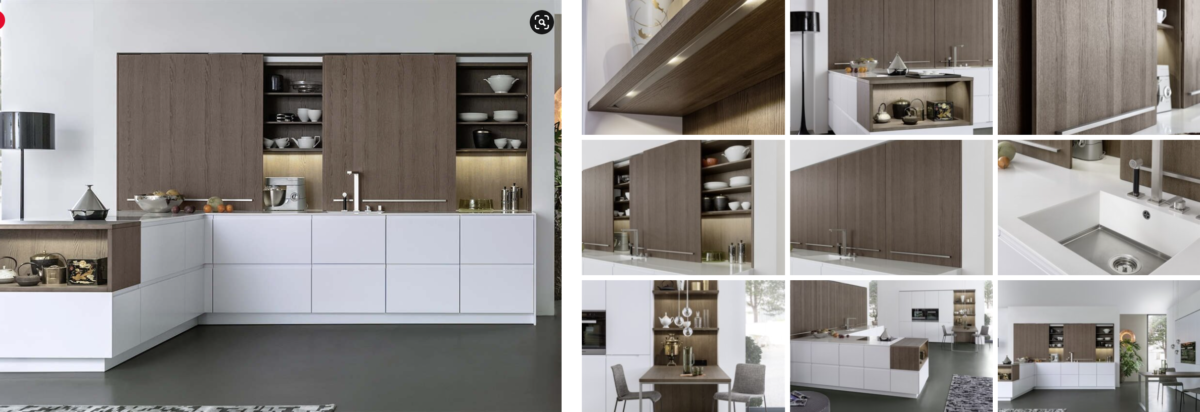

Kitchen cabinets can be quite expensive when compared with other elements of a kitchen remodel. As a kitchen designer you’re searching for top quality kitchen cabinets that endure the test of time and be able to reflect your customer’s preferences. This is the reason why it’s ideal to purchase from cabinet makers.

Why would you want to buy kitchen cabinets on the internet?

The convenience of buying kitchen cabinets online allows you the chance to evaluate and compare the various Kitchen Cabinets from China made by different manufacturers. You can also access all the details that you require to make the best decision on the website of the manufacturer.

How can you determine the lowest price on kitchen cabinets on the internet?

One of the most appealing selling points of the top kitchen cabinet manufacturers is their competitive pricing. They will often look at what their counterparts are charging and attempt to persuade you by offering a higher price. As a kitchen builder, you are able to make a decision easily and swiftly. In the end, you’re not wasting your time asking questions from a variety of firms.

It is a given for a trusted cabinet maker to offer the highest quality products that are constructed using top quality manufacturing techniques. In addition to using all-plywood products to construct their cabinetry, this company offers excellent services to customers, competitive prices and a pleasant overall experience.

Are you ready to purchase kitchen cabinets on the internet? Examine the cabinet maker of your choice according to the following criteria:

1. Quality

The most crucial aspect to take into consideration to consider is the high-quality cabinets you’re receiving. Ensuring that your customers receive high-quality Kitchen Cabinets from China constructed from solid wood and other sturdy materials will safeguard your name and will make everyone happy. A reputable manufacturer will provide cabinets that are able to last for a long wear and tear under the rigors of daily usage. They include RTA or all-plywood assembled kitchen cabinets that come in a variety of finishes options.

If you’re looking for the perfect cabinets that will reflect your client’s likes, be aware of the joints and the hardware. Dovetail joints are renowned for the strongest drawers. It is also possible to choose drawer glides and hinges with soft-close to maintain the long-term function of your drawers and cabinets.

2. Free cabinet design services

It is typical to see cabinet manufacturers request the final kitchen layout as well as exact measurements. It sounds simple but what happens is the procedure if a need for couple of changes occurs or you’re not certain of the exact requirements?

We recommend working with a cabinet firm which offers free cabinet services. They usually employ a staff of in-house kitchen designers that will work with you to provide a superior overall experience to your homeowner’s clients.

3. Transparent and seamless pricing process

Pricing will follow once you’ve finalized the cabinet designs you want for your kitchen remodel. It’s a vital element of any renovation. A good cabinet manufacturer will help you stay away from having to deal with unanticipated “extras” that may arise during the design process. The transparent and seamless pricing process can help you determine the total cost of the cabinets, no matter if you’re using cabinets that are preassembled, and RTA cabinets.

You could get more attractive deals if you place your orders at times when your preferred cabinet maker is running a special typically during special occasions or national holidays, such as Father’s Days, Easter, or Christmas celebrations.

How Kitchen Cabinets from China cost?

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

Kitchen Cabinets from China

What is the cost of kitchen cabinets?

A 10×10 RTA kitchen may cost as low as $1,499 and constructed units for the exact area begin at $2000. Kitchen cabinets’ prices will vary significantly based on the quality and amount of cabinets you’re considering buying. Other factors, such as assembly and installation, greatly influence the price of cabinets. RTA kitchen cabinets as well as pre-assembled kitchen cabinets could have completely different prices for the same item, since you design and build RTA cabinets by yourself. RTA cabinets are shipped flat and unassembled. RTA cabinets are delivered in flat form and are not assembled (and thus are cheaper as pre-assembled kitchen cabinets). The cabinet options we offer comprise of natural wood, durable MDF and HDF and strong plywood. We strive to provide an array of choices and finishes that are suitable for your budget. Whether you’re seeking great quality cabinets at a reasonable price or a unique design to boost an existing home’s value. We provide an array of options that will help you discover the ideal cabinet for your home.

What kitchen cabinets are trendy?

Based on Google Trends, Kitchen Cabinets from China are in constant and high demand on the internet for the last five years. Kitchen cabinets made of Shaker have seen more than triple in search results in the US in the last five years. When it comes to color kitchen cabinets in gray, they have seen the largest increase growing by nearly six times over the same time frame. There are a myriad of ways to transform your kitchen. Picking a beautiful cabinet in natural wood will give you an immediate feeling of home, comfort and security. If you’re looking for contemporary kitchens, then you’ll be able to choose a style for your kitchen cabinets or surfaces that give a classy ambience, which can add the dimension to your home and provide amazing entertainment spaces.

How do I redesign my kitchen on my own?

Remodeling your kitchen is relatively easy with the right materials. It is crucial to plan with the appropriate equipment and receive the advice of a professional source. Cabinet assembly videos for kitchens can will be helpful once you’re ready to start building and putting up your cabinets. If you’re planning to redesign your kitchen by yourself, RTA cabinets are the kind of cabinet that are likely to meet your requirements. You can purchase the materials by credit card, conduct the work in stages, or pick sturdy and intelligent materials like MDF. A wood that is water-resistant is a fantastic method to protect your investment in your home and guarantee that your kitchen’s finished product will hold its value for many years to be. Take a look at our product gallery for additional ideas for your next remodeling project!

Should I opt for easy-to-assemble cabinets for kitchens?

Ready-to-assemble cabinets can make a huge difference in the amount you’ll save on kitchen remodeling. Also, online shopping will be essential since online shops can cut a lot of the expenses that physical stores does not, yet they offer identical products. The choice of the appliances you choose to purchase is equally crucial, and a smart option is to purchase new items rather than used products. Items marked as refurbished may often be demo products or simply removed from their original boxes which means you get the exact same item at less than the price.

Vertical Channelization Device (LCD)

Vertical Channelization Device (LCD) Traditional plastic/pedestrian barriers

Traditional plastic/pedestrian barriers