The fully automated vertical packaging machine utilizes the latest pouch packaging techniques for heating sealing multi-layer polymer pouches. It is a completely automated packaging machine. The bag making process uses the stepper motor subdivision technique, with high accuracy and an error of less than 1 millimeter. This is a great machine to use in packaging industries like food, pharmaceutical, agrochemical cosmetics, etc.

What to Look For In a Pouch Packaging Machine

The pouch packaging machine with automated technology is among the most effective inventions and there are many who specialize in the manufacture for these types of machines. There are several elements to be looking for when selecting the right machine. There are a variety of machines that are available with a variety of designs. Each model is specially designed to pack products in a certain fashion. The packaging market is an enormous opportunity as there are thousands of new products that are constantly entering the market.

Therefore, these machines are in high demand and have an enormous chance of growth in the future.

What are the Basic Features the pouch packing machine?

The primary feature of the pouch packaging machine is the accuracy of the packing process that ensures the right weight as well as the size and cut in the bags. They are constructed and designed to ensure that they exceed any quality standard. They make use of cutting-edge technology when creating these machines.

These machines provide the best sealing solutions because they employ the heat sealing method. These machines can help to fill pouches, seal them, and then cut them, too. This is all done all in one continuous process with these machines. They are particularly crucial for manufacturers that manufacture liquid or powder-based items.

Types of Machines

Machine that forms Envelope seal pouches the machine is able to measure the total size of the item and produces pouches with the printed film according to the print pitch. It also uses the heat sealing process. It aids in filling the pouches and seals and even cuts them. It is a continuous process. It comes with a vertical heating roller that is used for film feeding. It’s a mechanical drive heating roller seal.

The other pouch-making machine that is used for packaging pouches is the three-side seal pouch packaging, forming and filling machine which measures the quantity of the product, which could be in powder, granular or solid forms. Again, the pouches are created from printed film that is placed in the roll. The heat sealing process is employed when the pouches are sealed, filled and cut in one seamless continuous process. The machine is fitted with a Touch panel that allows central control as well as a control of the servo motor. This rotary system which performs the pouch’s filling, forming and sealing processes in a horizontal orientation aids in ensuring a longer filling time and, consequently, the highest quality sealing results. This permits a long time for sealing and assists in making pinholes less likely to form.

There’s another machine that is also a three-side seal pouch for filling and forming as well as packaging equipment with the same features previously mentioned and comes with a servo-motor system. Its length is modified via the control panel, as well as the bar sealing system that is sporadic. It has an exclusive, individual rotating cutter option on this device.

The pouch packaging machine can be employed to make food products, as well as fast food packaging, and manufacturers of powered and liquid products as well as other items. The industry of packaging is growing rapidly and has enormous potential in the years to come.

What is the process by which a vertical packing machine functions?

Vertical packaging machines utilize one piece of material which is then rolled around a central core, commonly known as rollstock. The entire length of packaging material is known by the name of film. The materials used for packaging can range from cellsophane, polyethylene foil laminates and paper.

How Automatic vertical packing machine factory cost?

Automatic honey straw filling machine Semen straw filling and sealing machine honey stick machine

Ketchup Baby Fruit Puree Liquid Doypack Spout Pouch Filling Capping Machine

Tray Sealer Fresh Food Meat Fish Tray Automatic Vacuum Filling Sealing Packing Machine

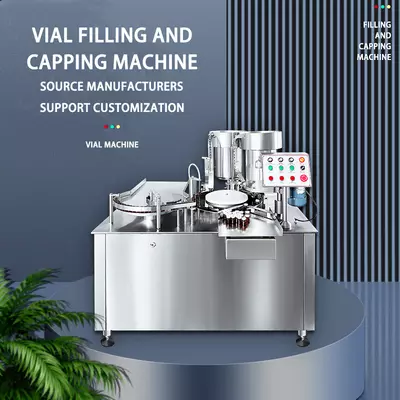

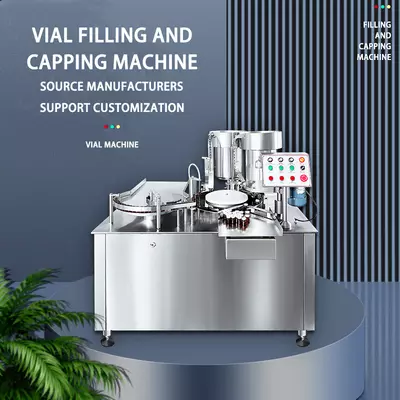

Pharmaceutical Injection Vial Filling Machine Automatic Vial Filling Plugging And Sealing Machine for 7-100ml Aseptic Vial

Beef Roll Fast Food Meat Tray Dinner Convenience Store Filling Sealing Packaging Machine

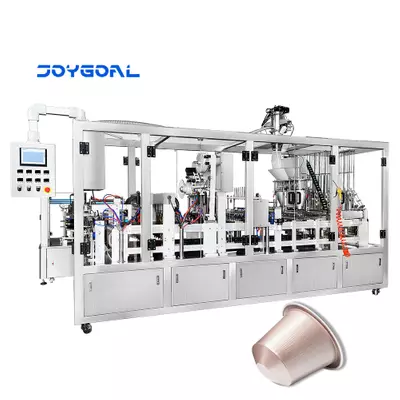

Automatic coffee capsule filling sealing bag packing cartoning mach

Semi Automatic Ice Cream Water Liquid Honey Juice Sauce Soft Drink Tomato Paste Servo Filling Machine

KFP-2 automatic nespresso coffee capsule filling and sealing machine and Vibration plate of hoist and flavour adding

What machine is employed for packing?

Strapping machines, banding machines, etc. Weighing machines include check weigher multihead weigher. Wrapping machines: flow wrapping, stretch wrapping, shrink wrap. Form machines to fill and seal bags, pouches, and bags.

What’s a capping device?

The bottle cap is the device which tightens or secures the cap of a container. Any business that packs products into containers, bottles or jars must have an option to seal the container. The most commonly used closure is one that is a cap.

What exactly is the significance of the term “packing machine?

A packaging device is the element of a system for packaging. The packaging is typically the final layer of protection that covers an item above the package (tertiary packaging) and ensures its integrity throughout the commercial and industrial process of transport, distribution storage.

How to Buy Automatic Packaging Machine?

There are two primary kinds of food packing machines: the automated packaging machine as well as the Automatic vertical packing machine factory. Automatic equipment is the most suitable type of packaging machinery used for food products because it is able to dramatically improve the efficiency of the food production and at the same time offers the most convenient use.

Remember that there are many kinds of packaging equipment that can be automated. It is advised to begin your process of selecting the best kind of packaging that is appropriate for the type of product you wish to efficiently pack. Therefore, if you’re looking to purchase one of these packaging machines it is essential to first find the best type of packaging which is highly effective in preserving the freshness of your food items.

Foods that are extremely perishable such as fresh meats or fresh fruits are perfect for vacuum packaging as the freshness of food is preserved by removing air effectively or reduced in order to bind aerobic microorganisms. A large amount of these microorganisms speeds up the process of deterioration in food. In contrast being devoid of them will reduce the rate of food degradation and thus extend its shelf-life. The same is true for other food items. This is the reason it’s important that research be conducted to enhance the packaging and prolong the shelf life of items that are essential in the sale of food products.

Another crucial point to remember is to select the right packing machine depending on the visual appearance and physical characteristics of the item. Granule and powdered foods are packed using packaging machines that are different from those that are used to pack liquid-based products. They are typically packaged by sealing machines or filling machines. These machines are ideal for sugar, tea powdered milk powder chocolates, powdered chocolates, and even tablets among other. Therefore, select the kind of equipment is most effective in preserving the quality of these items.

Another crucial tip to consider is to verify the cost. Note that each model and brand of automatic packaging machines is unique to its own characteristics and benefits. Certain models are inexpensive in comparison to similar models from other brands; however, the features aren’t as extensive. Equipment that is used for less stages of packaging food products needs devices with fewer specifications. Get more info about Automatic vertical packing machine factory

However the food products that require additional stages of packaging to ensure the freshness require more features, making the equipment more costly. So, it’s best to be aware of the essential stages of food packaging included in the machine.

For example, in the past the majority of soda bottling companies utilized separate equipment for filling bottles and capping equipment. Nowadays, there are automated packing machines that complete both of these processes like the automated filling of bottles and capping the bottles. In this scenario, the single machine that performs both of these tasks is cheaper than purchasing separate machines for each step in the process of packaging food.