Diamond dies are extensively used in a range of industries. They are used to draw tools in products made of soft wire (copper as well as aluminum wire) and metal wires (stainless steel or tungsten, as well as copper plated steel wire). Die components are synthetic diamonds or natural diamonds that offer high-performance in terms of hardness and abrasion.

What is the purpose of drawing dies?

A die that is used to form cups-like objects from sheet metal, which is then pushed through it with a punch and then kept from twisting through a blank holders that is used to hold the outside edge of the metal in place.

What is PCD?

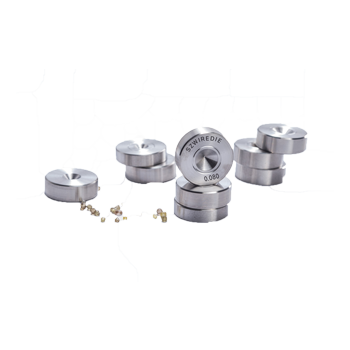

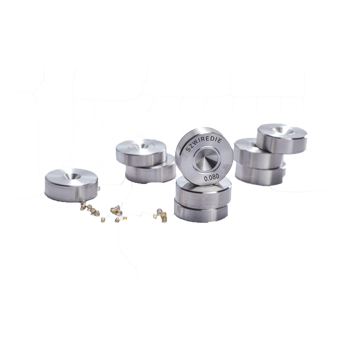

Paramount Die manufactures polycrystalline diamond (PCD) wire drawing dies which can be utilized for a variety of drawing purposes. PCD wire drawing dies provide a high resistance to wear and a superior surface finish for wire. Die dies are suitable for use in both ferrous and non-ferrous wire drawing. Get more info about ND Drawing Dies.

What is the process of making dies?

Forming operations involve creating a shape in materials like plastic or sheet metal by applying the force (compression tension, compression or both) and depend on the properties of the material’s mechanical. Die for forming is usually manufactured by tool and die makers and then put in production following the mounting of presses.

What are wire dies?

Wire drawing dies are instruments equipped with specially-designed, highly polished slots through which wire can be drawn in order to reduce its diameter. They are equipped with a metal case and a nib that is made of the Tungsten carbide (TC)

How can you tell the distinction between drawing as well as drawing deep?

Deep drawing and sketching are similar to stamping. The main difference is the fact that stamping tools are created to split sheets into the shapes necessary, while drawing tools produce deformation. To achieve this drawing tools have radiuses edges, while stamping tools feature sharp edges.

What effect does wire drawing have?

Wire drawing is the eroding or torsion of valve’s seat or disc material due to placing the disc and seat extremely close, but not entirely close to the position of shut-off.

What is the process of drawing wire?

The process of drawing wire consists of drawing the rod by pointing it, then threading the pointed end of the rod through a die, and then attaching the rod to the drawing block. The block, driven to rotate with an electric motor draws the rod that is lubricated across the die decreasing the diameter of it and expanding its length.

Diamond can be incorporated into wires?

While the material of choice is similar to the material used in single crystal diamond drawing die It can be applied to a diverse variety of applications, including large diameter wires and thin wire as it is available in larger dimensions.

What’s the significance of diamond?

The most popular uses of diamonds are used for ornamentation, and as industrial abrasives to cut hard materials.

What is a dies tool?

Tool or die that imparts a desired form and form or finish on a product. Some examples include perforated piece that metal or plastic is extruded or drawn and the forms made of hardened steel to produce the designs on medals and coins through pressure, and hollow molds that are used to form the shapes into which plastic or metal is made.

Advantages and Disadvantages of Wire Drawing Dies

Every kind of wire drawing tools has distinct specific characteristics. The wire drawing die made of genuine diamond is most costly and is extremely difficult to process. However due to the anisotropy inherent to natural diamonds, the degree of hardness differs greatly within the radial range and it’s easy to cause significant wear in a particular direction. This is why natural diamonds are best suited for processing wire that has a smaller diameter.

Despite the low hardness of the die made of cemented carbide, but the high-quality wire drawn using the cemented carbide die, and poor surface roughness, the wear resistance of the cemented carbide die is low and the lifespan of the die is limited. The wire drawing die coated with CVD has a high wear resistance because of its diamond-like performance. The roughness of the surface of wire drawing is comparatively minimal, however the manufacturing process of CVD coating the wire drawing die is a complex process and the process is extremely difficult and expensive. If the coating wears out the die wears quickly, making it not only challenging to maintain the quality of processing however, it is also not able to be used again, and is only scrappable.

While the drawing tool can be utilized to process all sorts of alloy and metal materials such as copper, steel molybdenum and so on. The drawing dies of various materials each have their own processing capability. When drawing dies from different materials are utilized to process the same wire rod the wear pattern and the duration of service differ. Thus, suppliers of wire drawing die and their judicious selection of drawing dies’ materials is essential to ensure efficient use. Drawing dies made from various materials offer relatively good processing objects.

The reasoning behind drawing mostly relates to the matching of the physical, mechanical and chemical characteristics of the drawing wire rod and die to get the longest life of the die. For instance the drawing of copper wires with similar diameter, the life of the polycrystalline diamond is about 300-500 times longer than the carbide die, 80 to 100 times longer than that of the nickel-based die 50 to 80 times more than using the carbide tool when drawing molybdenum-coated wire and 20-60 times more than that of the carbide-based die for using carbon steel. The lack of research regarding the matching theory for drawing dies and wire rods in China will eventually lead to blind choice and waste of resources. It could be that the influence of one aspect will cover the effects of the other.

“S&Z Wire Die Co.,Ltd supplies long-lasting dies and tools for Wire and Cable Industrial application. Our goal is to be a global supplier of wire drawing dies and tooling for the wire and cable industry while providing the dies and tools of the finest quality with the shortest lead-times in the industry.”

Our aim is to be the top global supplier of wire drawing tools and precise tools for the wire and cable industries, the trusted supplier that can provide high-quality products, knowledge, expertise, and supply chain efficiency that all customers require to be competitive in a global marketplace.